HT Tool Overview

The latest generation of High Temperature tool was designed to conduct logging in harsh wellbore conditions with temperatures up to 305 degree C and with the presence of H2S. The tool includes gamma ray and casing collar locator (CCL) for depth correlation, temperature sensor, pressure sensors and conventional flowmeter (turbine spinner). The tool is available in real time mode.

Main Advantages

- The surveys can be conducted in the steam injectors and geothermal wells in temperatures up to 305-degree C.

- The tool can provide wellbore steam injection profiles to understand which perforations are open intervals.

- The transient temperature survey in steam injectors can be conducted to obtain formation intake zones to understand unswept areas.

- The production profile for low temperature and dry steam geothermal wells can be recorded.

- The presence or absence of cement behind pipes will not affect the data quality.

The advantages listed above make this tool the most cost-effective steam injection and geothermal well profiling tool. The flow profile data can be used to determine the efficiency of injection and perforation performance.

Integrity Challenge

Integrity issues in steam injection wells can have unforeseen impact on adjacent production wells. This is due to the migration of heated fluids at shallow depths from the steam injectors resulting in corrosion in the nearby production wells. It is essential that during completion make-up that all joints are correctly made up within the recommended torque range to minimize leak paths.

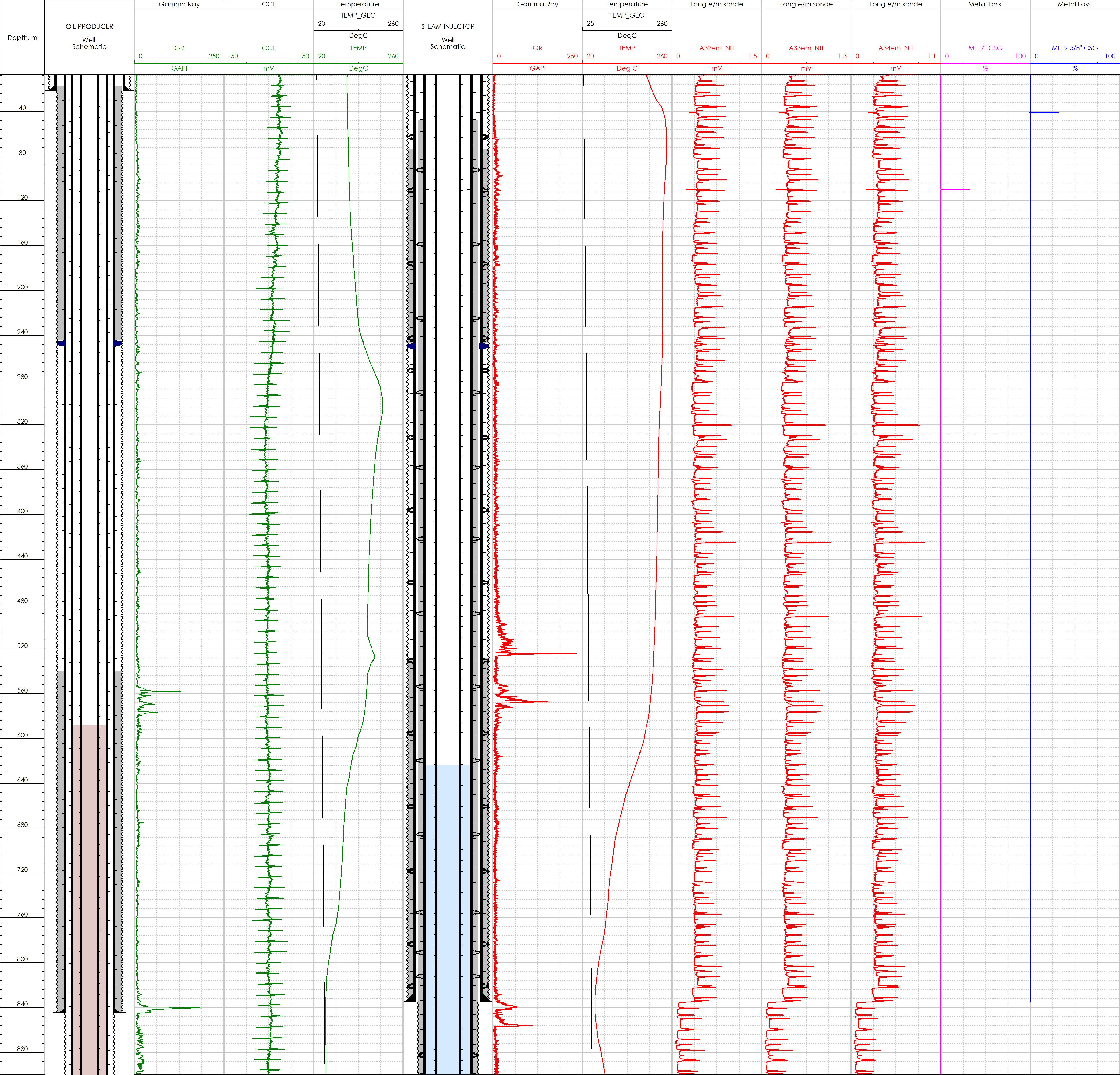

High Temperature Logging Results

The well is a vertical oil producer drilled in 2016. After drilling the well was completed with 9 5/8” casing, a 7” production casing and a 3.5” progressive cavity pump (PCP) completion. The well was drilled as an infill well in a field with heavy oil and with steam injector wells nearby.

In June 2022 after 6 years of production, the average wellhead temperature was approximately 70 degree C, it suddenly increased sharply to 130 deg C. To understand why the temperature had suddenly increased a decision was made to shut the oil producer to cool down Well Head temperature and record temperature profile. The log data indicated that the upper section of the well had heated to a maximum temperature of 205 degree C at a depth of 300 mbdf. The client suspected that there was communication between a nearby steam injector well and the oil producer. To confirm this assumption, the steam injector was closed in and 3 days after the shut-in period a high temperature tool was run in the steam injection well. The log data indicated that the upper section of the well was heated up to a maximum temperature of 260 degree C at a depth of 38 mbdf. The temperature curves indicated a downward crossflow from 41 mbdf to 260 mbdf. The temperature curves, recorded in both wells, indicated that there was a steam breakthrough at the upper section of the production well. To understand the steam injector well integrity failure, it was decided to run a corrosion log in this well. The well was cooled down and corrosion data was recorded from the surface to 900 mbdf. The EMDs data indicated the presence of a localized defect in the 7” casing at a depth of 110 mbdf, below a casing coupling. In addition, a localized defect was identified in the 9 5/8” casing at 41 mbdf. However, it should be noted that there were no indications of any defects in the completion string. Based on the temperature and corrosion data, the steam injector was worked over. During the workover it was identified that a pup joint in the completion string located below the tubing hanger had been insufficiently torqued. This in all probability would have been the entry point for the steam in the A annulus. Additionally, the steam had moved from 110 mbdf (defect in the 7” casing) upwards to 41 mbdf and entered the formation across the defect in the 9 5/8” casing. The client decided to install a patch to cover the defect in the 7” casing to avoid steam flow into the formation.

Cyclic steam injection will result in expansion and contraction of the tubing and casing strings which puts additional stresses on connections which have not been made up properly which could result in leak paths. Possible solutions include correct make up torques, expansion collars in casing to reduce wellhead growth and seal bore extensions in tubing to accommodate tubing movement.

More case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us