Integrity Challenge

Ensuring a strong cement bond in the annulus is crucial and one of the effective methods to achieve this is by utilizing a multistage packer and ensuring proper centralization. Additionally, an external coating on the inner pipe can reduce the risk of corrosion migration from the outer pipe to the inner pipe. This becomes particularly critical when the outer annulus had a poor cement job with little or no cement while being exposed to a corrosive aquifer. The potential failure of multiple barriers in this scenario can have severe consequences, including the occurrence of an oil leak to the surface. This can result in harm to personnel, the environment, the asset and company reputation.

Corrosion Logging Result

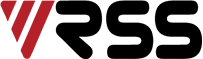

One example when corrosion logging was conducted and multi barrier metal loss on the outer casing and inner casing was detected is shown below:

The well is a barefoot horizontal oil producer drilled in 2003. The well was completed with a 13 3/8” surface casing, a 9 5/8” intermediate casing and a 7” intermediate liner. A 4.5” ESP completion string was run in hole.

In 2008 during a workover the completion string was pulled and a 4.5” straddle was installed in the 7” liner. A 3.5” ESP completion string was run in hole.

In September 2019 a subsurface integrity test (SIT) was conducted and the B annulus leak-off test (LOT) failed.

In September 2021 an EMDs corrosion log was conducted. The EMDs log data indicated the presence of two corroded intervals in the 13 3/8” casing. The first is at a shallow section of the well where the average metal loss was almost 70%. In all probability the severe metal loss in the casing is the root cause of the LOT failure. The second area is a localized interval with metal loss less than 20%. The 9 5/8” casing had two intervals of metal loss. The first one in the shallow section of the well where the corrosion from the 13 3/8” casing and migrated to the inner 9 5/8” casing. The average metal loss across this interval was 20%. The second corroded interval was in the 9 5/8” casing located below the 13 3/8” casing shoe where the 9 5/8” casing is the only barrier; the metal loss was less than 20%. Based on the corrosion log data it was decided to run a 7” scab liner to eliminate a possible leak to surface.

All case studies

Looking for more information?

Get in touch with us and our representative will get back to you

Contact Us